INTRODUCTION

Most of the people are unaware of the fact that number of components used in Oil Extraction from various Oil well in Sea Beds are machined in CNC Machines for their precision and quality as this is a highly risky work in nature.

There are number of manufacturers of those components in India as well as overseas for providing these kinds of products to satisfy the needs of Oil Extraction Companies. As the components work in high pressure, high temperature and highly corrosion environment these are needed to be replaced at a certain time interval and hence the demand of these is very high in market.

Our this user is also in manufacturing of various parts and their complete assemblies related to oil fields. This user had a requirement of a turning machine with Length of 6 Mtrs and swing diameter of 1 Mtr. With this specification the new machine comes with a very heavy price tag.

User has a conventional turning machine with almost same specification, user asked us to convert this conventional turning into full CNC machine. We agreed and the results were outstanding.

Technically there are few major differences between conventional Machines and CNC machines which are as mentioned below:

| No | Specification | Conventional Machines | CNC Machines |

| 1 | CHUCK CLAMPING | MANUAL | HYDRAULIC/PNEUMATIC (AUTO) |

| 2 | AXIS COMMANDS | MANUAL | AUTOMATIC NC COMMANDS |

| 3 | ACCURACY LEVELS | LOW (LEADSCREW USED) | HIGH (BALLSCREW USED) |

| 4 | QUALITY LEVELS | MODERATE | HIGH |

| 5 | CYCLE TIME | HIGH | LOW |

| 6 | OPERATOR SKILL LEVEL NEEDED | HIGH | LOW |

| 7 | PROFILE MACHINING | DIFFICULT | EASY |

| 8 | TOOL POST | MANUAL CHANGE | AUTOMATIC CHANGE |

In the above table you can see the major differences between conventional and CNC machines and can analyze the edge of CNC machines over conventional machines. Though in Some big Size machining products the suitable chuck is manual as it provides better holding torque in general Hydraulic or Pneumatic chucks are replacing them.

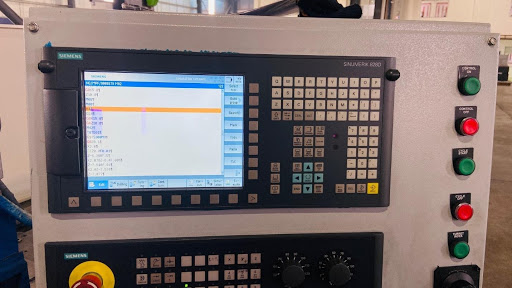

In this case we had major challenge to change the leadscrew of X & Z Axis to ball screw and modify the mechanical arrangements accordingly, after that the Automatic Tool Post (Turret) of Duplomatic was installed and the CNC System Siemens 828D was installed.

User approached us for a solution we provided a cost effective solution as mentioned below:

NEW CNC COST

| No | Specification | Remarks |

| 1 | NEW CNC MACHINE 6 MTR LENGTH SWING DIA 1 MTR | APPROX INR 80.0 LAKHS |

| 2 | DELIVERY TIME | 4-6 MONTHS |

With above table we can analyze that the cost of New CNC Machine with the same specification will be Approx. INR 80.0 Lakhs with a lead delivery time of 4 to 6 Months. With Advance of INR 40.0 Lakhs upfront with Purchase Order.

RETROFITTING COST

| No | Specification | Remarks |

| 1 | OLD CONVENTIONAL MACHINE COST | APPROX INR 8.0 LAKHS |

| 2 | BALLSCREW COST (GROUNDED) | APPROX INR 4.0 LAKHS |

| 3 | TURRET (DUPLOMATIC) | APPROX INR 5.0 LAKHS |

| 4 | CNC SYSTEM & ELECTRICAL ITEMS | APPROX INR 8.0 LAKHS |

| 5 | LABOUR CHARGES | APPROX INR 4.0 LAKHS |

| 6 | COMPLETION TIME | 3 MONTHS |

CNC SYSTEM USED – SIEMENS 828D

As you can analyze from the table given above the total cost of Project was INR 29 LAKHS/-. When calculated with the cost of new CNC Machine with the same specifications the savings yield was INR 51 lakhs/- with three months early delivery time.

The overall costing can be further reduced if the application varies as Cheap old conventional machine can be procured, Ball screw can be procured of Rolled type, Turret can be procured of Pragati as the costing differs exponentially.

Please find the pictures below for your ready reference.

Leave a Reply